The growing demand of packaging accomplishing with the EU directive on reusable packaging has boosted our R&D department to develop specific solutions for the Circular Economy, Greener Planet and Sustainable Growth.

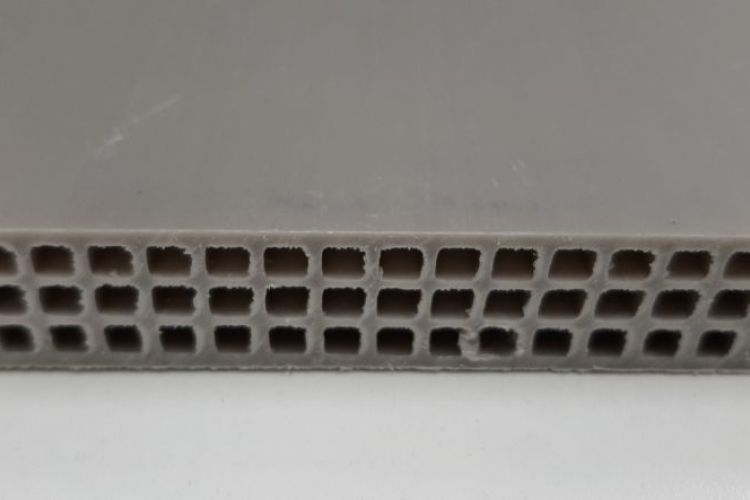

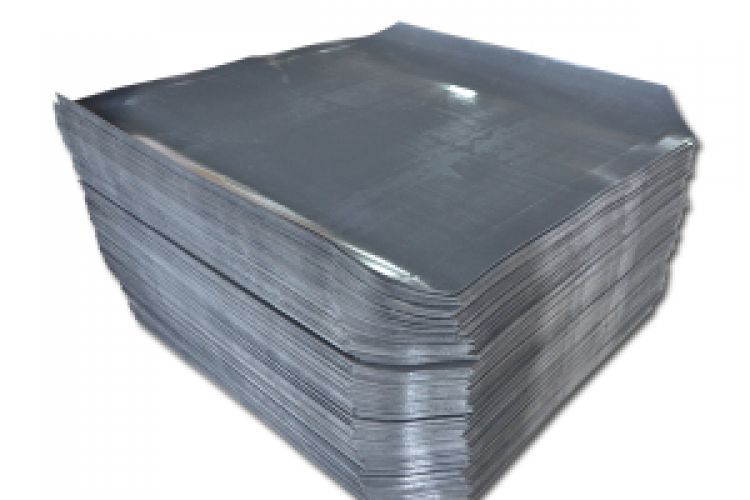

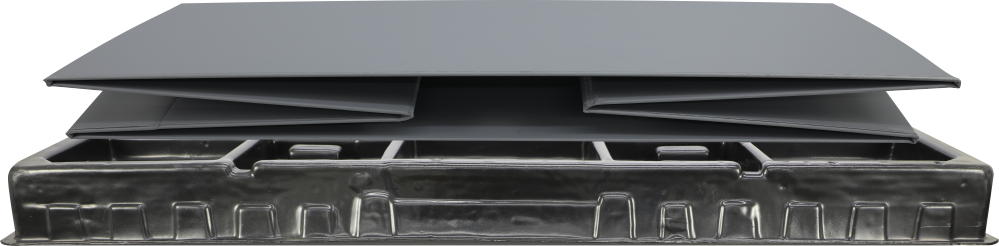

We are proud to present our series of machines for the production of Box Pallet Sleeves made out of PP hollow profile sheets:

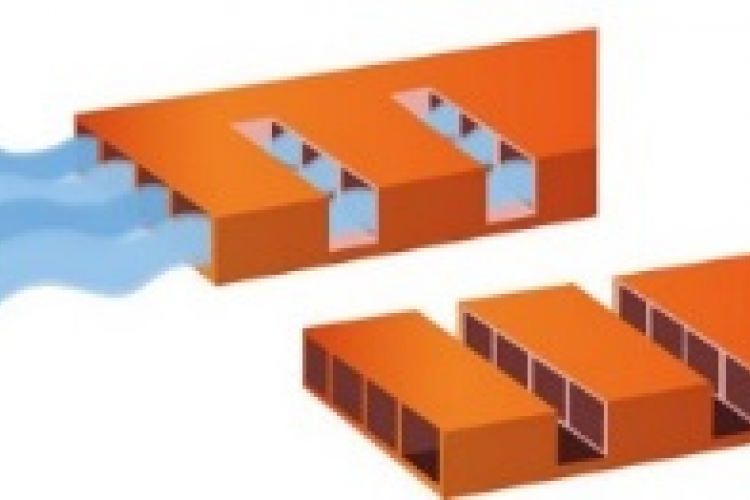

- Hot creasing machines for Box Pallet Sleeves: semi automatic machines to hot crease in V or W shapes pp hollow profile sheets, to manufacture Box Pallet Sleeves in any variety of sizes and sheet density. Such machines are modular as they can be supplied as follow:

- with one single hot creasing station

- with 3 simultaneous hot creasing station to hat crease in one step a semi box pallet sleeve (half a sleeve)

- with 6 simultaneous hot creasing station to hat crease in one step a full box pallet sleeve

- Hot creasing machines for Inspection Windows of Box Pallet Sleeves: semi automatic machines to hot crease in V and W shapes pp hollow profile sheets, to generate the inspection window in a box pallet sleeve.

- Hot welding/joining of a sleeve or 2 semi sleeves: semi automatic machines to hot weld and join a sleeve or 2 semi sleeves together. The hot welding can be curried out either by butt welding or by overlapping welding according to specific box pallet design and specifications of the PP hollow profile sheets.

Additionally we can supply Edge Rolling and Sealing machines to edge roll and seal the top and bottom part of the Box Pallet Sleeves.

Almost all of such machine can operate as stand alone solutions or integrated in an in-line solution according to the specific box pallet sleeve design and customer’s production request.