It was the end of the sixties when my father Marco Terragni was leading a team of engineers of his company Covema (Milano/Italy) to develop a specific small die and sizer/calibrator to extrude a plastic hollow profile sheet. The specific location where such R&D program took place was one of the various factories belonging to Covema and specifically it was the one named R.I.A.P. (Ricerche Industriali Applicate alle Poliolefine) s.r.l in Zingonia (Bergamo / Italy).

The result was encouraging and from a narrow die and sizer it was immediately after engineered a larger one to extrude a 1250 mm useful width plastic hollow profile sheet. It was the year 1971 and the first CARTONPLAST extrusion line and CARTONPLAST sheet came to this world!

The plastic raw material used to make such hollow profile sheet was a blend of PP and PP and subsequently PP copolymer.

My father named such extrusion line and extruded sheet CARTONPLAST and it registered its name.

We can find some track of such registering in the Kenya Gazette 19 July 1974:

In Class 17 - Schedule III

CARTONPLAST

B.20388- Plastics in the form of sheets, blocks, rods tubes and plates. Covema S.R.L., an Italian company, of 1 Via Fontana, Milan, Italy, and c/o Messrs. Kaplan & Stratton, advocates, P.O. Box 40111, Nairobi.

28th June 1971

Later on various international patents had been registered both at the name of Covema and Marco Terragni world wide for the specific type of die and sizer for the extrusion of CARTONPLAST.

It was already very clear to my father and to Covema that CARTONPLAST was:

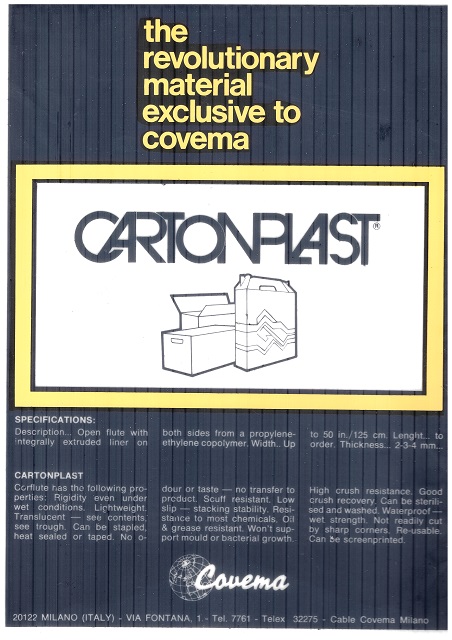

“the revolutionary material exclusive to Covema” for the production of reusable and recyclable boxes as you can see in the hereby posted scanned image of an original A4 format of CARTONPLAST sheet from the early seventies.

It clearly says:

SPECIFICATIONS:

Description….Open flute with integrally extruded liner on both sides from a polypropylene-ethylene copolymer. Width….up to 50 inches/125 cm. Length….to order. Thickness….2-3-4 mm…

CARTONPLAST

Corflute has the following properties: Rigidity even under wet conditions. Lightweight. Translucent – see contents, see through. Can be stapled, heat sealed or taped. No odour or taste – no transfer to product. Scuff resistant. Low slip – stacking stability. Resistance to most chemicals. Oil & grease resistamt. Won’t support mould or bacterial growth. High crush resistance. Good crush recovery. Can be sterilised ans washed. Waterproof – wet strength. Not readly cut by sharp corners. Re-usable. Can be screen printed.

Let's remember that all this happened in the early seventies....the idea of Circular Economy was already clear in my father's head!

CARTONPLAST THE REVOLUTIONARY MATERIAL EXCLUSIVE TO COVEMA (Milano-Italy 1971)