Converting Machines for Hollow Profile Sheet machines

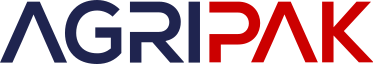

The growing demand of mono material, reusable and full recyclable Packages/Boxes in PP/PE Hollow Profile Sheets (Cartonplast) has pushed more and more AGRIPAK to study a solution to meet the increasing request of its customers.

After many years of study, designing, developments and improvements AGRIPAK presents its:

- Forming & Welding machine: to automatically assemble trays (for fruit, vegetable, fish, meat, industrial, pharmaceutical sectors, and so on) with/without bearing-corners, having head-folds welded inside and the upper-bands folded & welded to the inner-folds. The welding/assembly is carried out using hot air jets and this brings various advantages :

- production of a tray/package that is mono material: 100% PP or PE without any glue or hot melt that will make complicated the recycling of the tray/package. So a tray/package that is 100% recyclable

- a much cheaper solution compared to glue or hot melt as the welding means is just hot air so no need to buy expensive glue or hot melts

- a stronger welding as hot air is melting the two faces to be joined and therefore once the melting of the 2 faces occurs there is no possibility to separate them if not breaking them! On the contrary glue or hot melt may delaminate from the 2 faces to be joined especially under specific conditions like hot weather of very cold/freezing conditions or high level of humidity/rain and so on. Therefore this machine is granting a box that is at the end much more resistant then similar boxes/trays assembled with glue or ht melt. That means at the end elimination of possible delamination/opening of the boxes/trays with consequent lost of products.

- very low energy consumption: only 1,5 kwh

- very compact design that makes it possible to be easily loaded on a truck and transport it in the country sides to operate it to assemble locally during the harvesting season the necessary trays/boxes.