Excellent resistance to folding, tearing, traction, impact.

Not affected by chemical agents and mineral oils, water resistant, UV resistant, high/low T° resistant, light, compact, durable.

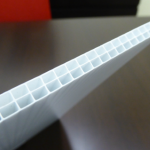

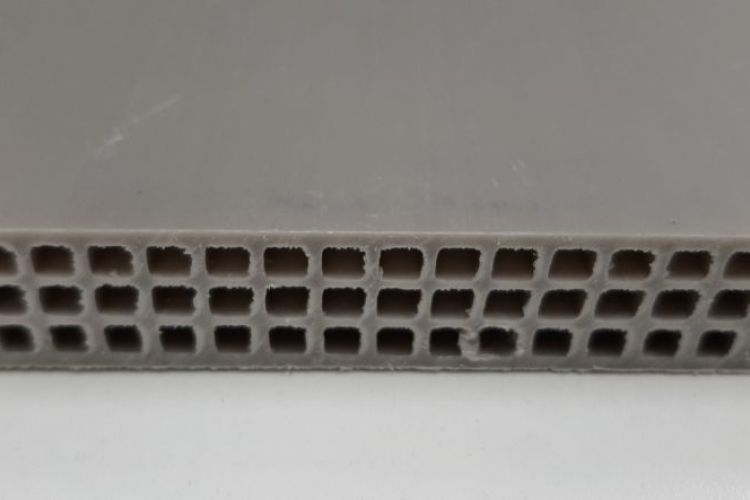

We are known among the first to have introduced into the world plastics-market the extrusion lines for the production of plastic hollow profile sheets (also called twinwall sheets or corefluted sheets).

Since so long proudly worldwide known under our trade mark: CARTONPLAST.

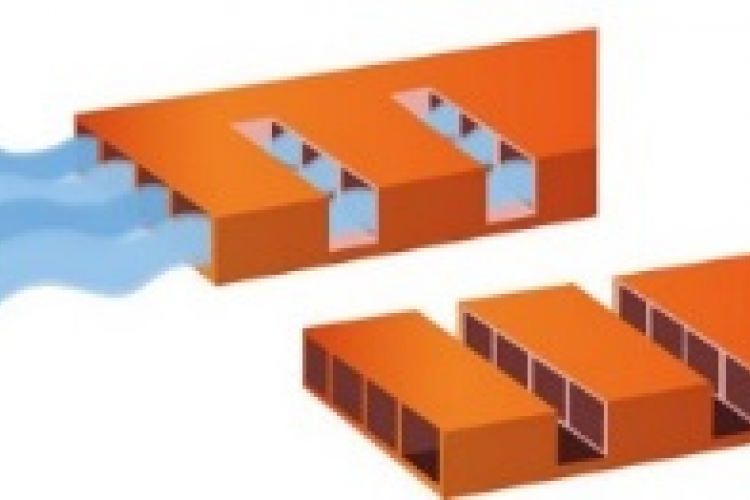

Our CARTONPLAST extrusion lines produce 1st quality corefluted sheets starting from PP, EPP (Expanded PP), HDPE and PET raw materials, in different thicknesses, weights, widths, ribs shapes & colours, as follows:

- thicknesses (from 2 to 25 mm)

- weights (from 250 to 4800 gsm)

- widths (from 1200 to 4000 mm)

- rib shapes (straight, sinusoidal, triangular, etc.)

- colours (any).

Our 1st quality hollow-profile sheet is obtained by extrusion via a T-die-head equipped with an inter-changeable spinneret/die, which offers the advantage of a quick die-change. Having a consequent considerable saving in terms of initial investment and of time necessary for the die-change during the production process.

At the end of the 90s, in cooperation with Reedy Chemical Foam, AGRIPAK proudly developed the CARTONPLAST exp series: an innovative-dedicated extrusion line family for the Expanded PP (EPP) hollow-profile sheets production by a successful mixing-recipe of standard PP with Chemical Blowing Agents (CBA).

This pioneer family of AGRIPAK extrusion lines is expressly conceived to grant a perfect and homogeneous foaming of the PP along the complete hollow-profile sheet width.

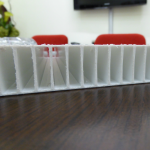

The Expanded PP (EPP) hollow profile sheets extruded by our lines present:

- an improved superficial smoothness for advertising applications

- an improved impact strength for packaging and building applications

- a higher energy absorption for packaging and building applications

- an excellent chemical resistance for building applications

- a low thermal conductivity for food packaging applications

- an easy sealing for interlayer pads and food packaging applications.

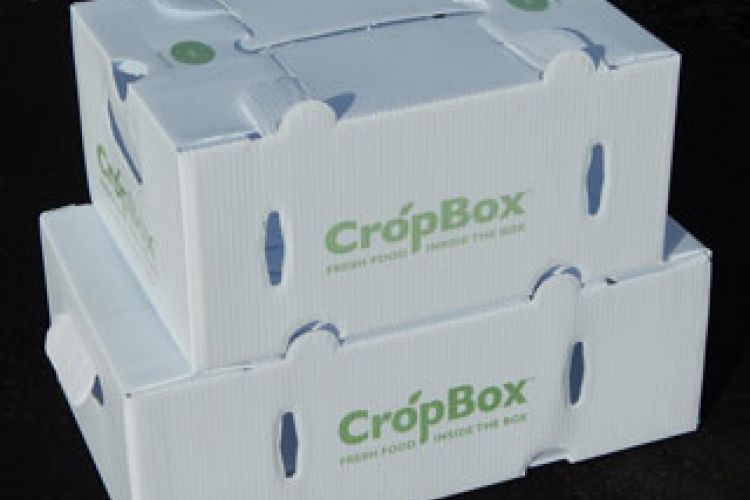

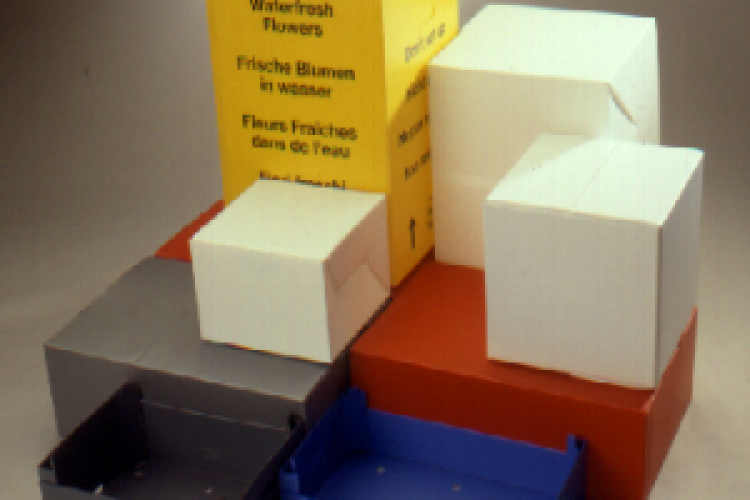

The hollow profile sheets extruded by our high-tech lines are widely used in the packaging field. They can be easily converted into any requested re-usable, re-cyclable or flat-storage box, having different shapes & size, by means of specific automatic case-makers machines equipped with slotter or flat & rotary die cutters.

They can be easily printed in different colours by flexographic, silk-screen or digital technique devices as well as being joined by sealing, hot-melting or staples devices.