SIGNO Seal & Cut Machine

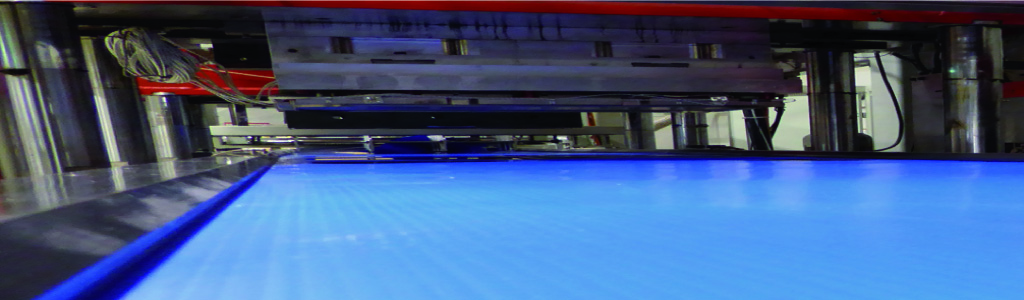

SIGNO is the new concept of sealing machine that contains in itself multiple devices, resulting from decades of experience in the extrusion and processing of corrugated polypropylene plastic sheets.

SIGNO is able to process any type of hollow profile sheet : alveolar, laminated bubbles (BubbleGuard) and honey-comb profiles, both in sheet or in reel.

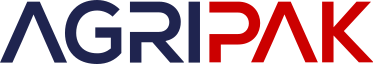

The innovative SIGNO sealing system for hollow profiles allows to achieve high sealing standards, compliant with the ISO 62 standard, regarding water absorption by the plastic sheets. The ISO 62 standard must be respected specially in the production of the interlayer pads in polypropylene alveolar sheets.Today, thanks to SIGNO, this standard can be fully respected and extended also to the production of the hollow profile boxes/packaging for food products (meat, fish, fruit and vegetables) and pharmaceuticals.

The lightweight structure of the sealing and cutting presses, as a result of a successful combination of technological innovation and the use of new materials, allows SIGNO to increase its production cycles without compromising the quality of its sealing and cutting of the final product, even at high grammages of the sheet.

Depending on the final product request, SIGNO can be equipped with various optional accessories for a full automatic production process starting from the feeding up to the final stacking station, where the sealed product will be properly stacked on a pallet, to be then packed and shipped to the final customer.

Through the touch panel, the operator can quickly change all the process parameters, in order to quickly find the optimal configuration to process sheets of different hollow-profile, thickness, weight and size.

The SIGNO series is also equipped with an industrial router that provides complete remote access to the machine’s process data : allowing our technicians to perform remote assistance and to our machine to interface (by our BI-BOX technology) with the process datas, with the interesting possibility of sharing & integrating the same datas with the most common internal management software.

The sealing of the hollow profiles has many advantages in terms of :

- resistance to compression and torsion : the air trapped inside the sheet cavities after the sealing, leads up to a 40% increase of the compression and torsion resistance of the sealed sheet itself, with the consequent relevant possibility to drastically reduce the sheet weight per square meter, without compromising its mechanical strength.

- thermal insulation : the air trapped in the sealed hollow profile, acts as an insulating barrier to the thermal exchange between the two external faces of the sheet, with a consequent important increase of the insulating properties of the final product.

- aseptic features : no bacteria, dust, impurities, or other organic products (such as : blood, liquids, insects,etc.) will penetrate into the hollow profile sealed cavities. These aseptic conditions are of primary importance in the food and pharmaceutical packaging fields.

- reusability : the hollow profile with sealed cavities can be cleaned quickly and easily, allowing multiple reuse of the final product. (circular economy)

- recyclability : no contaminant agents are entering into the sealed hollow profile, allowing the easy cleaning of its external sheet faces and its subsequent quick reintroduction into the cycle of plastics reuse - under flakes form - again in the process of new hollow profile sheets extrusion production. (circular economy)

- eco-sustainability : the high efficiency of the SIGNO machine sealing process allows also the sealing of extruded sheets with high percentages of recycled plastic (up to 80%), without compromising the sealing speed and quality. (circular economy)