AGRIPAK know-how in the spinning-field proudly dates back to the early 1960s.

At that time the Covema Co. team was involved in the development of a new technology for both the PP-Monofilament and the Rafia-tape : its innovative spinning line was proudly shown in June 1962 as the first in the world. The big development acquired then by the Polyolefin Rafias and by the Technopolymer Monofilaments in the:

- textile

- rope

- twine fields

is nowadays well-known by everybody.

But AGRIPAK team of experts, strengthened by this historical experience in the spinning & horizontal-stretching field, has continued to pursue for research & innovation. Recently proudly enriching our company spinning production-range by a successful NEW Monofilament Line for Structural Fibers: to be used for the Structural Reinforcement of any Cement and Concrete coverage (rocky, stony, etc.), in many building applications (flooring, paving, prefabrication, etc.) and with many advantages compared to the structural steel/metal fibers now in use, i.e : durability, ductility, higher compressive & flexural strength, no corrosion, higher adhesion to the cement matrix, highly-reduced cracking due to shrinkage and what’s more high workability of the shotcrete-jets, with homogeneous concrete distribution, no segregation and no wear of pipes or any other metal parts thanks to the total lack of bounce against any surface.

Most nowadays PET bottles/containers become waste after their usage, causing unavoidably environmental pollution.

To address this issue, the PET structural fibers made from recycled PET and used as additional structural reinforcement to cement or concrete can be a valid and effective solution.

Likewise as for the 3D printing, a new specifically designed plastic filament combined with Graphene has been successfully produced.

By these filaments you can now easily 3D print also “electrically conductive components”, with no need to add any circuitry after printing , cause you can print graphene wiring during your own creation 3D printing build-process.

This Conductive Graphene Filament extrudable by our dedicated line is overall appreciated for its main tech-properties of “high strength” and “superior conductivity”, thus numbering really a wide range of applications:

- in the electronics (i.e. : digital interfaces, game and music controllers, wearable electronics, etc)

- in the electromagnetic and radiofrequency shielding (i.e. : hospital equipment, telecommunications, etc.)

- in high-strength mechanical/functional tooling (i.e. hooks, drilling tool, etc.)

- in the everyday interface devices (i.e. : leds, touch sensors, low-voltage circuitry, sensing for proximity, position, acceleration, humidity or fluid levels measurement, etc.)

We remain at your complete disposal for more information on any of ours spinning lines of your interest:

- WOVENTAPE equipments, for the extrusion of textile Rafia in PP or HDPE.

- POLYTWINE equipments, for the extrusion of Rafia for ropes & twines in PP or HDPE.

- MONFIL equipments, for the extrusion of Monofilaments in PP, PE, PA or PET.

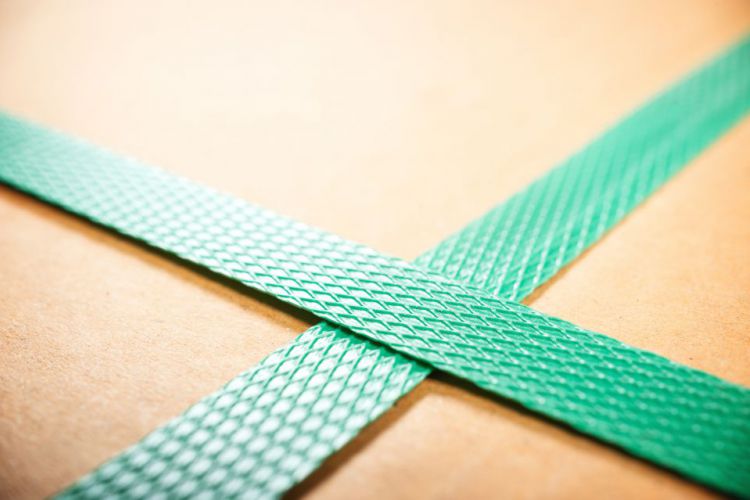

- PLASTICSTRAP equipments,for the extrusion of Strapping Tapes in PP or PET for the packaging field, developed by using the same stretching units of the aforesaid WOVENTAPE and MONFIL lines.

The main widths of the godets that can be installed on our stretching units are mm 600 - 1000 - 1200 - 1500.